CO2 Controller Inkbird ICC-500T

- 🌿 CO2 CONTROLLER: Inkbird ICC-500T, ideal for maintaining an optimal CO2 level in your growing spaces.

- 📏 DUAL DISPLAY: Simultaneous display of current CO2 level and set point for easy and accurate management.

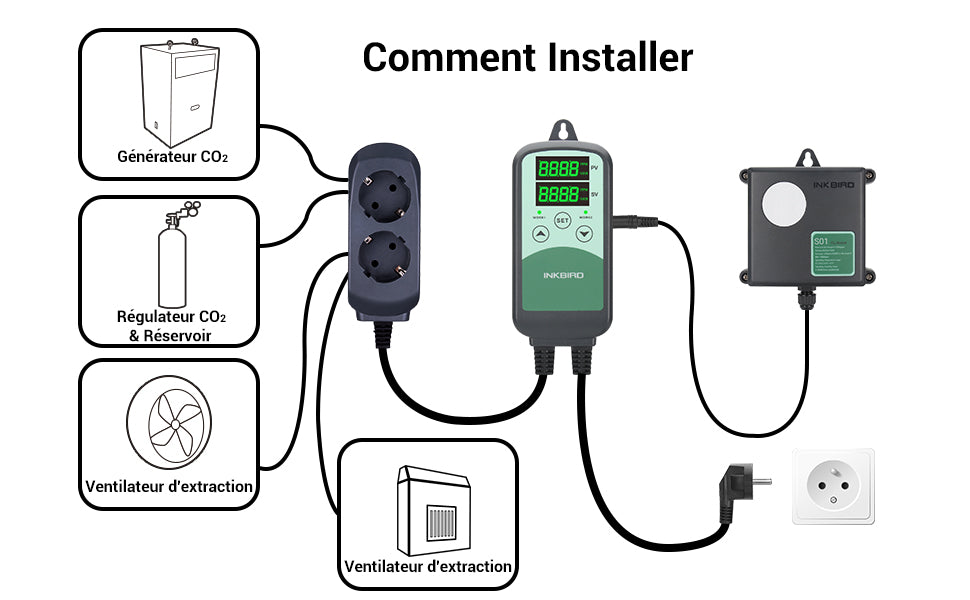

- 🔧 EASY TO USE: Ready to use, quick and easy setup, compatible with most CO2 equipment.

- 📊 ADVANCED FEATURES: Audible alarms if programmed thresholds are exceeded, easy calibration of the CO2 sensor.

- 🌍 VARIED APPLICATIONS: Perfect for greenhouses, grow rooms, aquariums and other environments requiring precise CO2 control.

To achieve optimal results, controlling the CO₂ level is an essential element of mushroom production.

With this controller, you can simply connect your ventilation system (intake or exhaust) to the device and set the thresholds according to the desired levels. Air renewal will therefore only occur when necessary, allowing you to save energy.

Recommendations:

During the incubation phase, a high level of CO₂ is beneficial (1000 to 2000 ppm), as it inhibits premature formation of mushroom caps and encourages the development of robust mycelium. However, excessively high CO₂ levels can slow mycelium growth and negatively affect mushroom quality.

Once the incubation phase is complete and the oyster mushrooms begin to form primordia (the first signs of mushroom caps), it is essential to significantly reduce CO₂ levels to promote proper mushroom growth. This reduction can be achieved by increasing ventilation in the growing room. Too high a level will cause deformities in the mushrooms, such as elongation of the stems and a decrease in cap size in the case of oyster mushrooms.

In the fruiting room, you must maintain a CO₂ level of 400 to 800 ppm.

Specifications

ICC-500T CO₂ Controller with S01 Probe

- Input power: 100 ~ 240Vac, 50 / 60Hz, 10A MAX.

- Output power: 100 ~ 240Vac, 50 / 60Hz, 10A MAX.

- Disconnection method: Type 1B

- Rated pulse voltage: 1500V

- Automatic operation: 6000 cycles

- Working environment: ambient temperature

- Storage temperature: 0 ~ 60 °C

- Storage humidity: 20 ~ 80% RH (no freezing or condensation)

- Measurement range: 0 ~ 9999 ppm

- Detection method: NDIR

- Probe operating temperature: 0 ~ 50 °C

- Operating humidity: 0 ~ 95% RH (non-condensing)

- Error: ± (30 ppm + 3% FS)

- Response time (63%): 20 seconds

- Instructions included. CE Certification

Recommendations

- Place the probe in a good spot in your room. If your space is poorly ventilated, or if internal air circulation is insufficient, air pockets may form that distort the CO₂ level measurements.

- In the fruiting room, note that the probe remains sensitive to humidity and water. Be careful not to wet it directly and avoid placing it in an airflow near the mister.