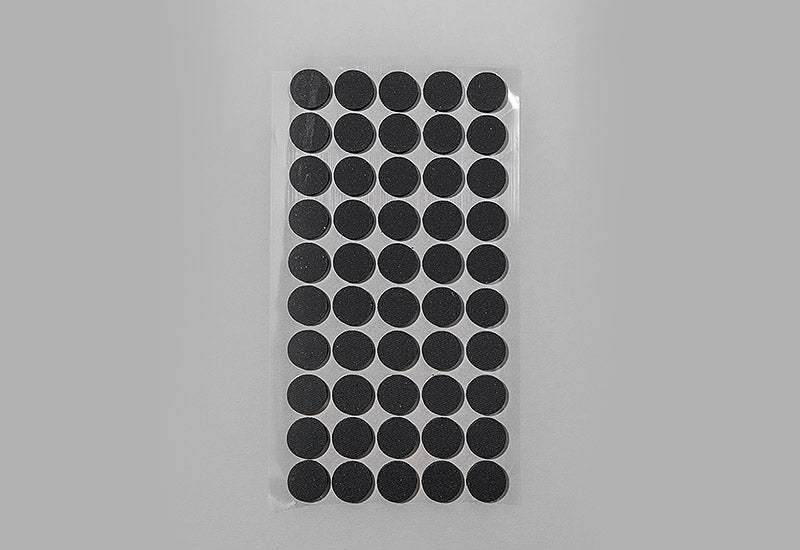

Self-sealing injection port

- Ease of use: Adhesive injection ports allow liquid cultures to be injected without having to open the container, reducing the risk of contamination.

- Cleanliness: the self-healing material of the injection ports closes after passing the needle, which helps protect the culture medium from contamination.

- Durability: Injection ports are made with strong 3M adhesive and are waterproof, making them resistant to harsh conditions. In addition, they are fully autoclavable and resistant to temperatures above 121°.

- Ease of application: It is easy to apply the injection ports to jar lids or grow bags. Simply clean the surface where you are going to stick the port, peel the port from the foil and apply it to the bag or jar. Remember to always clean the port with 70% alcohol before inserting a needle.

Perfect for injecting liquid cultures with a syringe into a jar or a bag of sterilized grains. This way, you don't even have to open the container and thus limit the risk of contamination.

Adhesive injection ports can be applied to jar lids or culture bags so you can inject and withdraw mycelium in liquid cultures while protecting your medium from contamination (molds, bacteria, yeasts).

Features

- Saves time and cleanliness compared to silicone techniques

- Self-sealing material. It closes after the needle passes through.

- Made with a strong 3M adhesive

- Waterproof

- Fully autoclavable, it withstands temperatures above 121°C

- Origin: U.S.A.

Usage

With a Unicorn bag:

- Clean the surface where you will stick the injection port.

- Peel the injection port off the sheet and apply it to the bag or jar.

- Note: always clean the port with 70% alcohol before inserting a needle.

With a jar:

- Drill a lid with a drill bit of about 5mm. Place an adhesive filter, pressing well on the edges to make it stick.

Tip for sterilization in pressure cookers:

Do not close the lids completely. Leave a small gap that will allow steam to escape, otherwise the injection ports or filters may come off due to internal pressure. This also helps prevent the formation of a "vacuum" during cooling, which can damage the filters. Cooling should be done in the cleanest possible environment to avoid contamination. Only open the pressure cooker when the temperature has returned to room temperature, and close the lids tightly at that time. If possible, work in front of a laminar flow.